IMPROVE YOUR PACKAGING

MatTop Conveyors

Handle bottles and other products, empty or full, and in single file lines or mass flow.

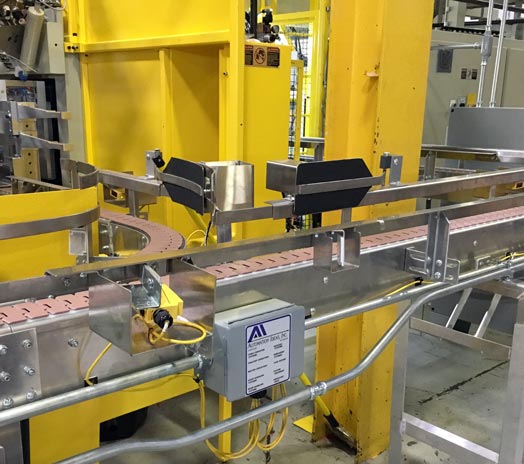

Automation ideas professional quality mattop conveyor systems are an excellent solution to a wide variety of products and large size change differences. Mat-top conveyors handle bottles, packages of finished product in nearly every orientation, empty or full. There are many different chain types and our engineering team will determine the best style for the application. Conveyors are built in aluminum or stainless steel construction with a variety of options for adjustable rail systems, enclosures, inclines/declines, and much more.

MAT-TOP CONVEYORS IMPROVE

Mat-Top Conveyors are very because of their versatility and customizability. They can be used in nearly every application from start to finish of your production process, and they easily integrate with existing production equipment. Mat-tops are ideal for companies that are constantly changing product types or companies that want the ability to improve line features in the future.

VERSATILE & CUSTOMIZABLE

MatTop Conveyor Systems

An excellent solution to a wide variety of product handling requirements.

Additional Improvements

Scrap

- Transporting plastic scrap and waste materials typically means using loud blowers and air duct systems. Mat-Top Conveyors are much quieter, and they can transport more materials than traditional air systems. This eliminates the need for dedicated scrap lines from each trimmer, ultimately saving space and money.

Bin Systems & Accumulation

- Mat-Top Conveyors reduce downtime by automating your inventory and accumulation processes. This is done through mass flow accumulation on the conveyor itself or through the integration of a bottle Bin System. For more information on Bin Systems please click here.

MatTop Conveyor Systems from Automation Ideas

If you are interested in our MatTop conveyor systems, or would like to learn more about any of our other conveyors, please contact us here or give our dedicated support team a call at (616) 874-4041.

Related Equipment

OPTIMIZING YOUR EFFICIENCY

Improving your workflow to help minimize downtime in your business!